|

November (2023)

Michelin: Announces Decision to Restructure Operations in Germany Link...

Michelin has announced its decision to gradually cease production at its Karlsuhe and Trier sites as well as the new tire and semi-finished production manufacturing at Homburg. The actions are set for completion by end of 2025. The decision is linked to growing competition of budget truck tires and lack of competitiveness of its German operation.

October (2023)

Michelin: Intends to Wind Down Tire Production at Its Ardmore, Oklahoma Site by 2025 Link...

Michelin is winding down tire production at its Ardmore site, with the intention of completing the process by the end of 2025 or sooner. Rubber mixing operations at the Ardmore site are expected to continue. Tire production will gradually shift to Michelin's other PC tire plants in North America. Michelin point to the fact that North America's passenger vehicle market is changing rapidly and profoundly, meaning despite substantial investments into Ardmore the site is not equiped to deliver tires at competitive costs that will meet evolving market demands. Fundamental market conditions driving the decision are:

- Dominance of light trucks and cross-over vehicles in North America requiring ever increasing tire sizes.

- Transition of market to electric vehicles.

- customers’ requirements for continual improvements in rolling resistance and other sustainable materials technologies.

Precise timing has not been determined for specific phases of the wind-down. Based on the current outlook for market demand, however, operations at the Ardmore plant are expected to continue trending gradually lower until mid-2024, when the first wave of staffing reductions will occur. Additional reductions are expected to occur in phases through 2025 as transition plans are finalized. Michelin’s rubber-mixing operations at the Ardmore plant supply other factories in North America. After tire-manufacturing activities wind down, these rubber-mixing operations are expected to continue for the foreseeable future.

Michelin: Considering the Future of One or More Tire Plants in Germany Link...

Michelin has opened talks with union representatives at its plants in Germany that may result in the closing of one or more of the four Michelin plants in Germany. Initial indications are that Michelin is looking to withdraw from the production of truck tires in Germany, which would mean the closure of the Karlsuhe and Trier plants and a reduction in activities at the Homburg plant. Talks are ongoing.

July (2023)

Michelin: Launching Air X Sky Light Aviation Tires Link...

Michelin is launching the Michelin Air X Sky Light aviation tire in the North American market. The tires are designed to cut both weight and costs for airlines. Debuted in Europe at the 54th Paris Air Show in June 2023, the Michelin Air X Sky Light tire is a new radial tire technology developed for commercial aviation. As a result of multiple performance breakthroughs, the overall tire weight has been reduced by 10%-20%. While offering a better performance over the long-term Landing Per Tread (LPT), the tire’s lifespan is extended by an additional 10%-20% from previous generations.

June (2023)

Michelin: Equiping French Postal Service Delivery Vehicles ith UPTIS Tires Link...

The MICHELIN Uptis puncture-proof tire will be fitted to 40 La Poste vans in the Hauts-de-France region (North of France) by the end of 2024. Three initial vehicles will be put into circulation as of June 27, within the framework of a two-year partnership between La Poste and Michelin. By 2024, nearly 40 La Poste vans fitted with the MICHELIN Uptis airless tire will deliver letters and parcels in the Lesquin, Valenciennes and Douai sectors, in the Hauts-de-France region (North of France). Particularly suited to last mile delivery, the MICHELIN Uptis airless technology removes any risk of punctures and limits the premature changing of tires. Michelin’s main target market for the Uptis prototype is light truck fleets intended for professional use, and particularly deliveries.

May (2023)

Michelin: Selling Russian Activities to Power International Tires Link...

Michelin has signed an agreement with Power International Tires LLC for the purchase of its two Russian companies: Michelin Russia Tyre Manufacturing and Camso CIS. Power International Tires is one of the main tire distributors in Russia and has a presence throughout the country.

Michelin: Investing $100 million USD at Junction City, Kansas Track Plant Link...

Michelin has announced that it will invest $100 million USD in its Junction City, Kansas plant to increase production capacity of tracks for agricultural equipment.

March (2023)

Michelin: New Tweel Tires for Truck-Mounted Forklifts Link...

Michelin have partnered with Hiab USA Inc. to offer Tweels on their MOFFETT Truck-Mounted Forklifts thus expanding Michelin's airless radial tire technology into a new segment where uptime is critical for efficient material handling and delivery. The MICHELIN X TWEEL TMF tire is designed to eliminate downtime, with its no-flat construction and improved machine stability when handling heavy loads, while maintaining excellent traction and operator comfort. The development of this specific size was a true collaboration between Michelin North America, Hiab and the field-testing partner, Mans Lumber & Millwork.

Michelin: $300 Million CAD Investment in Nova Scotia Plants Link...

Michelin has announced a $300 million CAD investment into its Canadian operations to accelerate sustainable mobility and improve its environmental footprint. The investment, part of Michelin’s global growth strategy, will see the installation of new technologies and equipment in Michelin’s three Nova Scotia production facilities to respond to market evolution. This includes manufacturing tires for the growing electric vehicle (EV) segment; larger rim size tires for passenger and light truck vehicles; as well as improved fuel efficiency for commercial trucks. In addition, the electrification of key parts of the manufacturing process will reduce carbon emissions at the plants. A key part of the multi-year plan is the $140 million CAD expansion of Michelin’s Bridgewater plant.

January (2023)

Michelin: UPTIS Testing with DHL Singapore Link...

Michelin has started testing UPTIS airless tires with DHL in Singapore. By the end of 2023 nearly 50 DHL Express commercial vehicles will be fitted with UPTIS airless tires. Michelin state that airless technology is a key step in the development of a fully sustainable tire by 2050. Today, 20% of tires are prematurely scrapped due to a puncture (12%) or uneven wear (8%) linked to poor pressure. According to an internal Michelin study, UPTIS airless technology could prevent the disposal of 200 million tires per year worldwide, or 2 million tons of material.

November (2022)

Michelin: Ready to Integrate Pyrowave's Recycled Styrene Monomer Into Elastomer Production Link...

Pyrowave has reached a major milestone passing Michelin's quality tests with a 99.8% pure recycled styrene monomer produced from polystyrene waste. The recycled monomer can now be integrated into industrial elastomer batches allowing a finished product with fully traceable and segregated recycled styrene, this contrasts well versus mass-balance, credit-based content schemes.

October (2022)

Michelin: Symbio Investing 1 Billion EUR in France to Accelerate Global Fuel Cell Technology Link...

Symbio, a Faurecia and Michelin 50/50 JV is investing 1 billion EUR through 2028 in its HyMotive project. This will be done in two stages: Stage 1: Acceleration and mass-production of Hymotive current-generation fuel cells in its Saint-Fons gigafactory (under construction). Stage 2: Hymotive will develop and industrialise new fuel cell systems built on disruptive technology. Symbio's production capacity in France is targeted to reach 100k cell packs per year by 2028. This will contribute to the global roll out of competitive fuel cell technology solutions and a fast ramp-up of Hydrogen-powered mobility.

July (2022)

Michelin: Coordinating WhiteCycle Project for Plastic Waste Recycling Link...

Michelin is coordinating the recently launched WhiteCycle project which aims to develop a circular economy converting complex waste containing plastic textiles into high value products. The WhiteCycle ambition by 2030 is to foster the annual recycling of more than 2 million tons of the third most widely used plastic in the world, PET. Composite industrial waste containing textile (PET) and other components from tires, hoses and multilayer clothes at the end of the product life cycle – which is currently difficult to recycle – could soon become recyclable. That material could go into producing new plastic for tires, hoses and clothes.

June (2022)

Michelin: Intending to Transfer Activities in Russia to Local Management by End 2022 Link...

After suspending its manufacturing activities in Russia on 15th March 2022, Michelin now confirms that it is technically impossible to resume production. The group is therefore planning the transfer of all its Russian operations by the end of 2022 and is considering transferring control of its administrative, sales and industrial operations to the current local management. Michelin Russia employs approximately 1,000 people, including 750 at the Davydovo plant, located about 100 kilometers from Moscow. The site has an annual production capacity of 1.5 to 2 million tires, mainly for passenger cars. Michelin’s sales in the country represent 2% of the Group’s total sales and 1% of its global car tire production.

April (2022)

Bridgestone: and Michelin Release rCB Position Paper Link...

Bridgestone and Michelin have released a position paper focused on their joint initiative to increase the use of recovered carbon black. The position paper outlines the reasoning behind this important call to action and the goals both Bridgestone and Michelin plan to achieve through this collaboration.

RCCL Industry Analysis:

Postioning Paper Summary

Initial Focus

Initial focus will be on pyrolysis and rCB initiatives in Europe and North America, other sustainable materials from ELTs will be considered in the future, these include: micronized powder, reclaim, devulcanised rubber and pyrolysis oil.

PCR/TBR ~80/20 blends representative of average ELT feedstock in EU and US with various grinding post treatment.

Key Requirements

- rCB must be recognised at a ‘product’ rather than ‘waste’ in every country

- rCB must meet the definition of a ‘product’ in every country

- rCB must comply with all chemical and product regulations (e.g. REACH in Europe)

- rCB should comply with the same trade regulations as applicable to vCB

- Certification requirements are: IATF 16949, ISO 14001 and ECOVADIS

- Traceability requires checking and verification of origin of ELTs. EU ELT/rubber goods must be collected from within the EU market.

Specification

Specification to be developed using a combination of vCB and new rCB parameters with reliance on ASTM D36 for final rCB test methods, initially using vCB as a reference.

Next Steps

Will work with industry leaders with their feedback on the position paper to better define next steps towards the final white paper.

RCCL Comments on Positioning Paper

No big surprises or major insight into actual practical use or technical requirements, these may be expanded upon in the white paper. The initial focus indicates use of a blended PCR/TBR feedstock which may be quite different to the approach taken by many pyrolysis companies which have focused on one particular tire type. Some of the indicated test parameters could prove problematical for rCB producers (both in maintaining specification and proficiency in doing the testing). Reliance of the ASTM D36 group is only satisfactory if there is significant input from tire/rubber industry participants. The emergence or acknowledgement of a commercially viable rCB technology leader/s would substantially accelerate the adoption process and would provide a better industry benchmark/reference.

March (2022)

Michelin: Suspends Industria Activity in Russia as well as Exports to Russia Link...

The Michelin Group is suspending its industrial activity in Russia, as well as its exportations to Russia.

Michelin: Interrupting Production at Some European Plants Link...

Due to the current crisis in Ukraine, and like many industrial players in Europe, the Michelin Group is facing major logistical and transportation issues in supplying its plants and delivering to customers. To optimize operations and adapt flow management, the Group has made the decision to stop production at some of its European plants for a few days in the coming weeks. Each site will decide specific duration and implementation.

October (2021)

Michelin: Expanding Resicare Bio-Based Adhesives Link...

Resicare, a Michelin subsidiary, is making progress expanding market opportunities for its bio-based, toxic-free, adhesives following a three year development program with Allin, a specialist plywood panel manufacturer. With respect to tires, ResCare installed a mobile resin production unit at Michelin's Olsztyn site, signaling the start of commercial operations. Several additional installations are planned in Europe and Asia over the coming months.

September (2021)

Michelin: Recycling PET Waste into Tires by 2024 Link...

Michelin is planning to use waste PET from plastic bottles in their tire reinforcing fibers as early as 2024. This was announced ahead of the German transporation show IAA in Munich.

April (2021)

Michelin: Increases Sustainable Content In MOTOE™ Tires Link...

Michelin has already incorporated 40% sustainable materials in the MotoE’s rear tires and 33% in the front tires, all while improving lap times. For these tires sustainable content comes from biosourced materials (e.g. sustainable NR and biosourced BR) or recycled materials (regenerated or reused materials such as end-of-life-tires). For these tires sustainable content was increased by integrating rCB from used tires using development partner, Enviro's process.

Michelin: Symbio Boosting Hydrogen Mobility Link...

Symbio, a joint venture between Michelin and Faurecia recently signed a contract with Safra to develop 1500 hydrogen fuel cell buses which will be equiped with Symbio's special 'plug and play' solution made of a 45 kW fuel cell combined with compressor and power converter. Symbio is also partnering with Stellantis which announced the sale of its first fuel cell powered commercial vehicles. Symbio's system will offer these vehicles 400 km range and refueling in minutes. Symbio plans to produce 200 k of its standard hydrogen systems per annum by 2030, having demonstrated the ability to adapt the systems to specific client requirements. Symbio has launched construction of the largest hydrogen fuel cell plant in Saint-Fons, France. It will be inaugurated in 2023.

February (2021)

Michelin: Building First New-Generation Tire Recycling Plant in Chile Link...

Michelin is launching the construction of its first tire recycling plant in collaboration with Enviro. The plant is based in Chile's Antofagasta region and will be capable of recycling 30kMTpa of earthmover tires. Work on the plant will start in 2021 with production scheduled for 2023. The total investment is more than $30million. The plan is to reuse 90% of the recovered materials in various rubber products including tires, conveyor belts and AV products. The remaining 10% will be used for plant energy generation.

January (2021)

Michelin: Simplification and Competitiveness Project for Activities in France Link...

Michelin is launching a reinforced simplification and competitiveness plan to improve agility and performance of its manufacturing, corporate and administrative operations in France. The plan will rely on negotiationg a three-year framework agreement that will not entail layoffs and does not rely on plant closures. The development ambitions for France consolidate premium and speciality tires as well as adding high-value businesses such as service, sustainable materials, energy transition and recycling. The group intends to improve its competitiveness by up to 5% per year the various functions. Individual plants will be impacted differently depending upon operations and the competitive environment. The impact could be reductions of 2300 jobs over the next 3 years (1100 in offices and 1200 in plants). Up to 60% of the reductions may be based on voluntary early retirement with the remainder on Group-supported voluntary severances. Michelin is committed to create a new job position for every elimination through new businesses or local revitalisation programmes.

December (2020)

Michelin: MOTOE™ Sustainable Racing Tires Link...

Michelin have introduced a new range of sustainable e-motorbike racing tires. The tires incorporates bio-sourced and regenerated materials. Racing applications provide Michelin with a rich source of materials development opportunities.

November (2020)

Michelin: Joint Development Agreement with Pyrowave Link...

Michelin and Pyrowave have announced a joint development agreement to fast-track an innovative plastic waste recycling technology. Through the Pyrowave‑developed technology, it is possible to generate recycled styrene from plastics found in packaging, insulation panels and/or household appliances. This recycled styrene is an important monomer: it is used in the production of polystyrene and synthetic rubber for tires and a large number of consumer products.

Michelin: Launches e.Primacy Tire - Its First CO2 Neutral Tire at Time of Purchase Link...

Based on life-cycle assessments, the e.Primacy range is the first for which an environmental product declaration has been published. The full life-cycle analysis includes considerations for raw materials, manufacturing, logistics, use of product and services, end of life and recycling. The tire provides high levels of energy efficiency in use, while projects to avoid or absorb residual carbon emissions from non-use items complete the cycle. These projects include reduced energy household appliances and tree planting.

September (2020)

Michelin: Coordinating Blackcycle - A Major European Project for Recycling End-Of-Life Tires Into New Tires Link...

Coordinated by Michelin, uniting 7 industrial partners, 5 Research & Technological Organizations and an innovation cluster into a European consortium in 5 countries. The BlackCycle project aims to enable a massive circular economy of tyres by designing world-first processes to produce new tyres from end-of-life tires (ELTs) Officially funded by the EU in May 2020, the BlackCycle partners have announced the launch of the project involving 13 organisations,1 in a unique European public-private partnership, that will demonstrate the technical, environmental, and economic viability of world-first circular processes. The consortium will develop specific solutions to produce sustainable raw materials for tires: ELT collection and feedstock selection, pyrolysis2 optimisation, oil refining and valorisation, furnace process optimisation, and sustainable tire performance assessment.

April (2020)

Michelin: Partnering With Enviro For Tire to Raw Material Development Link...

Michelin is partnering with Enviro to develop and industrialize on a large scale an innovative pyrolysis technology to recycle tires at the end of their life. Enviro's innovative technology enables production of high-quality products such as recovered carbon black, pyrolysis oil, steel or gas, These products can then be re-incorporated into the production circuit of different industrial sectors. The partnership has four key points of focus: - Deploying Enviro's pyrolysis technology on a larger scale

- Michelin will take a 20% stake in Enviro, the group will support development of Enviro through board representation

- A project to build a factory to industrialise the technology

- A joint supply agreement between Michelin and Enviro

Discussions are ongoing between the two companies with the objective to conclude a final agreement by mid-2020.

March (2020)

Michelin: Early Closure for Dundee, UK Plant Link...

Tyre production at the Michelin plant in Dundee has ceased early as a result of the coronavirus pandemic. The company has shut the plant after 50 years of manufacturing and agreed to pay the workers their full entitlement to wages through to the planned closure date in the summer. Michelin first announced the plant closure in 2018 the target closure date was originally mid 2020.

January (2020)

Michelin: Joint Development Agreement with AVA Biochem for 5-HMF Commercial Scale Production Link...

AVA Biochem AG, based in Zug, Switzerland has developed a water-based process for the conversion of sugars into the 100% bio-based molecule 5-HMF. This platform chemical is ideally positioned to replace petroleum-sourced chemicals in various mass-market applications including resins and adhesives where toxic formaldehyde is replaced. AVA Biochem has entered into a joint development agreement with Michelin aiming to establish the world's first commercial-scale production plant for 5-HMF.

October (2019)

Michelin: Closing La Roche-Sur-Yon Site in France Link...

Michelin has announced plans to close the La Roche-Sur-Yon truck tire plant by the end of 2020. A recent 70 million euro investment in the site did not translate into expected results, this was due to structural transformation of the premium truck tire market in Europe and internationally. The European market is characterised by no growth, intense competition and an increasing entry level brand segment.

September (2019)

Michelin: Announces Decision to Close Bamberg Site, Germany Link...

The Michelin Group has decided to cease activities at its Bamberg site in Germany by early 2021. The site mainly manufacturers premium 16 inch PC tires, a market segment seeing sharp decline in global demand as well as strong competition from Asian manufacturers.

Michelin: Upgrades Bad Kreuznach Plant for SUV Tire Production Link...

Michelin has completed the upgrade of the Bad Kreuzhach plant in Germany. A new high tech SUV production line for 18 and 19 inch rim diameters has replaced an older line which produced lower (14 and 15 inch) rim size tires.

July (2019)

Michelin: Considering Future of Bamberg Plant in Germany Link...

Michelin is considering the future of its car tire plant in Bambery, Germany. This plant specialises in the production of smaller sized pc tires, a market facing intense competition from imports as well as a declining domestic market. Michelin has entered into negotiations with the plant's works council and unions to examine future options.

June (2019)

Michelin: Strategic Development Partnership with GM for Uptis - Airless TireTechnology Link...

Michelin and General Motors unveiled a new generation of airless tiretechnology for passenger vehicles at the Movin'On Summit in Montreal, Canada. The Michelin Uptis prototype (Unique Puncture-proof Tire System) will be developed further in a joint research agreement with GM. The aim is to validate the prototype with a goal of introducing Uptis on passenger models by 2024.

January (2019)

Michelin: Acquires Indonesian Tire Manufacturer Multistrada Link...

Michelin has acquired leading Indonesian tire manufacturer PT Multistrada Arah Sarana Tbk. Acquired production capaacity is more than 180 kMT strategically placed in Indonesia's fast-growing market.

November (2018)

Michelin: Planning to Close Factory in Dundee, Scotland. Link...

Michelin plans to close its factory in Dundee, Scotland by the middle of 2020. Strong competition form cheap tires from Asia as well as lower demand for smaller premium tires was a strong driver for the decision. Conversion of the facility to larger premium tires was not considered financially viable.

September (2018)

Michelin: Restarting Production at Starr OTR Plant Link...

Michelin North America Inc is restarting production of giant earthmover tires at its Starr plant in South Carolina. This plant was idled early 2016 due to a downturn in the market.

July (2018)

Michelin: Acquires Camso Link...

Michelin and Camso have reached an agreement whereby Michelin will acquire Camso. The two companies' OTR operations will be combined to form a new division to be managed from Camso HQ in Quebec, Canada.

Reporting net sales of US$1 billion, Camso has been designing, manufacturing and marketing OTR mobility solutions since 1982. Camso is a market leader in rubber tracks for farm equipment and snowmobiles, and in solid and bias tires for material handling equipment. It also ranks among the top three players in the construction market, in track and tire solutions for small heavy equipment.

June (2018)

Michelin: 2048 Goals for Tires Made with 80% Sustainable Material and 100% Tire Recycling Link...

Michelin announced its ambition, during the 2018 Movin'On summit, that by 2048 all of its tires will be manufacturerd using 80% sustainable materials (recycled and renewable materials) and that 100% of all its tires will be recycled.

Michelin estimate that currently its tires are made from 28% sustainable material (26% biosourced: natural rubber, sunflower oil etc and 2% recycled matertials such as steel or recycled powdered tires).

March (2018)

Michelin: Announce Recommended Cash Offer for All Shares of Fenner Plc Link...

Michelin announced that it intends to acquire Fenner PLC. Headquartered in Hessle, United Kingdom.

Fenner is a global leader in reinforced polymer technology with 2017 annual revenues of £655 million. It provides conveyor belt solutions and reinforced polymer products for the mining and general industrial markets. Fenner operates two divisions: (i) Engineered Conveyor Solutions (ECS), the second largest producer of heavy conveyor belts and a global player in the heavy and complex conveyor belt solution market and (ii) Advanced Engineered Products (AEP), a leading player in diversified polymer-engineered products.

Michelin see the acquisition as a perfect strategic fit for leveraging its expertise in high technology materials.

October (2017)

Michelin: Acquires Lehigh Technologies Link...

Michelin has acquired Lehigh Technologies, a specaility materials company using patented cryogenic mill technology to transform rubber from end-of-life tires and industrial goods into materails for new tires and other products, thus reducing the amount of raw materilas initially required.

The acquistion demonstrates Michelin's intent to use its expertise in materials to markets beyond tires, in particular in relation to the use of advanced rubber recycled materials in tires and no-tire applicaions.

RCCL Industry Analysis:

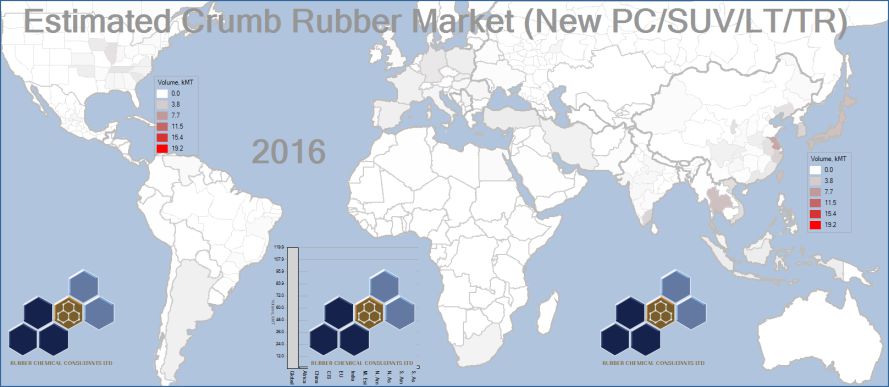

Analysis Snippet: Rubber Crumb Market for New Tires There are a wide range of crumb rubber products available on the market, each of which has different performance characteristics. Crumb produced using the cryogenic process offers advantages over other processes because the material undergoes limited chemical degradation during processing. Tire manufacturers are looking closely at crumb rubber to partially address their sustainability objectives. Use of crumb rubber provides for material reuse (part of the 'virtuous circle') and also means replacement of virgin materials. The newer technology crumb rubbers such as those produced by Lehigh Technologies have broadened the use envelope allowing for incorporation in new tire compounds (especially truck treads) at increased loadings. Rubber Chemical Consultants 2016 market volume estimates for crumb rubber usage in new passenger car (PC), sports utility vehicles (SUV), light trucks (LT) and truck (TR) are provided in the figure below. The total estimated market demand for 2016 is approximately 120 kMTpa. Forward projections show substantial increases. Further information and comprehensive analysis is available by arrangement.

Michelin: Doubles Capacity at Truck Plant, India Link...

Michelin has started up a new production line at its truck plant in India. Capacity for X Guard truck tires will be raised to over 30 k tons pa.

January (2017)

Michelin: X Tweel Turf Introduced for Golf Carts Link...

MICHELIN X TWEEL TURF airless radial tire has a unique spoke design which helps dampen the ride for enhanced ride comfort when driving over gravel, uneven pavement, and bumps. The full width poly-resin spokes provide lateral stiffness results for improved side-hill stability. High performance compounds and an efficient contact patch offer long wear life and excellent traction.

August (2016)

Michelin: Acquiring Levorin Pneus e Camaras Link...

Michelin is acquiring Levorin Pneus e Camaras, a Brazilian manufacturer of bicycle and motorcycle tires, in order to strengthen its global development capabilities for two-wheeler tires and consolidate its presence in Brazil.

July (2016)

Michelin: Adding Capacity for Radial Agricultural Tires, Campo Grande, Brazil Link...

Michelin is adding capacity for radial agricultural tires at its plant in Campo Grande. The move is designed to capitalise on high potential growth in a region with only 6% radialisation in agri tires.

Michelin: Planning Production Facility in Mexico Link...

Michelin has confirmed its plans to build a tire-production facility in central Mexico to produce high-end tires for passenger cars and light trucks

June (2016)

Michelin: Targetting €1.2bn cost savings between 2017 and 2020 Link...

Michelin is focusing on its competitiveness plan targeting cost savings of €1.2 billion between 2017 and 2020.

Key parts of this initiative include: deployment of new business processes and information systems, raw material costs due to optimisation of raw material content and engineering lighter tires, capacity utilisation focusing on large 100k MT capacity plants.

RCCL Industry Analysis:

Analysis Snippet: Michelin Competitiveness and Impact on Materials There are many facets to sustainability within the tire industry. The reduction in use of materials is one key pillar being adopted by many of the top tire manufacturers, each manufacturer typically having target reductions for new tire lines. Material reduction can be achieved via design optimisation and/or use of improved materials, examples of this can be seen in casing components where plies have become thinner and in improved liner barrier technologies allowing thinner gauges for equivalent performance. An additional benefit to compound volume reduction is that there is less material from which to loose energy when a tire rotates. This also has a benefit for sustainability in use. The RCCL Tire & Rubber Chemical Database© system incorporates tire component weight reduction into forward material projections – the final calculated material demand results from a complicated mix of projected tire demand based on future tire size requirements and type (as well as construction, component design and composition).

October (2015)

Michelin: European Reorganisation Link...

Michelin announced a European reorganisation rationalising retread production in Europe with the closure of retread sites in the UK, France, Germany and Italy and also announcing the planned closure of the Balymena truck tire plant in Northern Ireland. Coupled with these announcements were additional investments in PCR production in the UK and a resource reallocation programme in Italy.

February (2015)

Michelin: Expanding UHP PC Tire Capacity in Hungary Link...

A previously postponed investment is now being proposed to increase capacity of 18" tires in Hungary.

November (2014)

Michelin: Opens World’s First Plant for Airless Radial Tire Link...

Clermont-Ferrand, 20 November 2014 — Michelin has opened its newest plant in North America, which will produce the innovative MICHELIN® X® TWEEL® Airless Radial Tire™ for commercial applications. An idea first conceived by Michelin research engineers in the United States, the TWEEL is a revolutionary non-pneumatic tire that changed the configuration of a conventional tire, bringing together the tire and the wheel assembly into one solid unit. The TWEEL comprises a rigid hub connected to a shear beam by means of flexible, deformable polyurethane spokes, all functioning as a single unit. Unlike conventional tires, the TWEEL has no air, thereby solving what had seemed to be the unavoidable challenge of chronic flat tires that plagues the landscape, construction, contracting, refuse/recycling and agricultural industries.

October (2014)

Michelin: Inauguration of Capacity Expansion at Tigar Link...

Pirot, Serbia – Michelin and its Tigar Tyres subsidiary, on 9 Oct, inaugurated the new Tigar Tyres plant in Pirot, where the French group has invested €215 million to expand capacity. The expansion of the entry-level-segment production plant will create 500 new jobs in the region, according to a Michelin pres statement. The new plant is equipped with high-end technology, allowing to increase the yearly production capacity and to reach 12 million tires by the end of 2016.

June (2014)

Michelin: Plans to Reconfigure Production Base in Hungary Link...

In response to the adverse trends and aggressive competition in the European truck tire market, which remains volatile and 23% down on its historic peak in 2007, Michelin has announced its intention to close its truck tire production plant in Budapest. The decision reflects the fact that extending the facility is no longer possible, due to its location in an urban setting, and that improving its competitiveness would require excessive upgrading with new equipment. The plant’s production of tires sold under the Taurus, Riken and Kormoran brands would be terminated in mid-2015. The Budapest plant’s production will be mainly reallocated to the Michelin facilities in Olsztyn, Poland; Zalau, Romania; and Karlsruhe and Homburg, Germany.

March (2014)

Michelin: Plan to phase out tire production at Pictou, Nova Scotia Plant Link...

Michelin will phase out production at the 43-year-old plant in two phases. It will eliminate production of small-dimension car tires by June 30 this year, affecting about 200 employees, the company said, and then phase out the remaining capacity by June 30, 2015. Despite the phase-out of tire production, the Pictou County plant will remain open, producing some high-performance tires and tire membranes and continuing as a rubber-compounding site, supplying other company factories.

September (2013)

Michelin: Sustainable Development Objectives Link...

Michelin have presented six major objectives for 2020. From a material perspective the objective to 'improve performance of products by at least 10% over 2010 levels whilst using fewer raw materials' clearly indicates the drive in this area. The other objectives can be viewed in the article.

August (2013)

Michelin First 6 Months Financials Ending June 2013 Link...

€1,153 million in operating income with nett op income of €507. A 1.5% decline in volumes.

June (2013)

Michelin to close subsidiary Icollantas in Columbia Link...

Michelin has decided to discontinue the manufacturing operations of its local subsidiary Icollantas citing continuing losss based on economic and structural factors.

|