|

March (2024)

Goodyear: Planning to Shut Down Shah Alam Tire Plant in Malaysia Link...

Goodyear is planning to shut down its plant in Malaysia on June 30 2024 as part of its Goodyear Forward corporate restructuring program aiming to deliver $1 billion in cost reductions by 2025.

Goodyear: Selling Certain Avon Motorsport Assets to UK Company Link...

Goodyear is selling certain Avon motorsport tire assets toTurbalvoroco Unipessoal Lda., which does business as Nova Motorsport. Nova Motorsport is part of SPC Rubber Group and will be located in Holt, Bradford-on-Avon where production is set to start this month, with product availability in 2H 2024.

January (2024)

Goodyear: Introduces Electricdrive™ 2 PC Tire with > 50% Sustainable Materials Link...

Goodyear has unveiled the latest tire in its ElectricDrive™ family: The Goodyear® ElectricDrive™ 2, an all-season electric vehicle tire enhanced with sustainable materials, improved rolling resistance and long-lasting tread life to maximize drivers’ EV performance. The new ElectricDrive™ 2 is the latest step in Goodyear’s sustainability initiative and contains at least 50% sustainable materials per tire by weight.

November (2023)

Goodyear: Rationalisation Plan for Closure of Fulda and Fürstenwalde Plants in Germay Link...

Goodyear is proposing to close its Fulda and Fürstenwalde plants in Germany as part of the company's Goodyear Forward strategic plan. The proposal replaces the previously announced plan to reduce production at Fulda by 50%. The new plan remains subject to consultation. Goodyear expects to complete the closure of Fulda by the end of 2025 and of Fürstenwalde by the end of 2027. The Company expects these actions to improve EMEA’s segment operating income by achieving annual run rate savings of approximately $60 million by the end of 2025, $100 million by the end of 2026 and $120 million by the end of 2027.

Goodyear: Announces Transformation Plan Link...

Goodyear has announced a transformation plan: Goodyear Forward, to optimise its porfolio and drive sustainable shareholder value. Key points of the plan from an operational viewpoint are:

- Strategic Alternatives for its Chemical Business, the Dunlop Brand and OTR Tire business.

- Cost Reductions looking at footprints, plant optimisation, purchasing, SGA, supply chain and R&D.

- Optimisation of brand and tier positioning and rationalising SKUs in USMCA

October (2023)

Goodyear: Collaborating with Visolis for Isoprene Production Via Upcycling Materials Link...

Goodyear and Visolis have announced a collaboration project between the two companies to produce isoprene through the upcycling of biobased materials. This collaboration is supported by a Small Business Innovation Research (SBIR) grant awarded to Visolis earlier this year. Isoprene is a hydrocarbon that is typically generated as a by-product from refining crude oil. Isoprene units are polymerized into long chains using a catalyst to produce polyisoprene, which is used as a raw material in manufacturing tires and other items. The Visolis and Goodyear collaboration will leverage Visolis' technology to produce high-quality isoprene from lignocellulosic feedstocks, which are non-edible biomass and agricultural materials.

June (2023)

Goodyear: Reducing Tire Production at its Fulda, Germany Plant Link...

Goodyear has started negotiations with its workforce at its Fulda, Germany plant with the aim of cutting production at the plant by 50% by the end of 2024. The action is deemed necessary to improve the business cost structure by decreasing high-cost capacity and optimising use of other EMEA plants.

January (2023)

Goodyear: Unveils 90% Sustainable Tire Approved for Road Use Link...

Goodyear has unveiled a demonstration tire comprised of 90% sustainable materials. This demonstration tire has passed all applicable regulatory testing as well as Goodyear’s internal testing.

The 90% sustainable material demonstration tire incorporates 17 featured ingredients across 12 different components, including:

- Carbon Black: Four different types of carbon black that are produced from methane, carbon dioxide, plant-based oil and end-of-life tire pyrolysis oil feedstocks. These carbon black technologies target reduced carbon emissions, circularity and the use of bio-based carbons, while still delivering on performance.

- Soybean Oil: A bio-based resource that helps to reduce Goodyear’s use of petroleum-based products. While nearly 100% of soy protein is used in food/animal feed applications, a significant surplus of oil is left over and available for use in industrial applications.

- Silica: A high-quality silica produced from rice husk waste residue (RHA silica), a byproduct of rice processing that is often discarded and put into landfills.

- Polyester: recycled from post-consumer bottles by reverting the polyester into base chemicals and reforming them into technical grade polyester used in tire cords.

- Resin: Used to help improve and enhance tire traction performance. In this demonstration tire, traditional petroleum-based resins are replaced with bio-renewable pine tree resins.

- Steel: Bead wire and steel cord from steel with high-recycled content, which is produced using the electric arc furnace (EAF) process. The utilization of the EAF process allows for steel to be produced with reduced energy use and higher recycled content. The EAF process has the potential for lower greenhouse gas emissions in comparison with steel produced using a blast furnace.

- ISCC certified mass balance polymers from bio- and bio-circular feedstock.

October (2022)

Goodyear: Closing Cooper Tire Melksham UK Plant Link...

Coooper Tire (acquired by Goodyear a year ago) has announced the proposed closure of its Melksham, UK site (subject to consultation). The Melksham site has struggled to be competitive for some time with the additional burden of the challenging current environment. The closure is expected to be complete by the end of 2023.

Goodyear: Consolidating Motorcycle Tire Production In Europe Link...

Goodyear have outlined a proposal to consolidate European premium motorcycle tire production at its Montlucon, France production site following the closure of the Cooper Tire UK facility. LT production at Montlucon will be moved to other European production sites. These changes are planned to take effect by end of 2023.

September (2022)

Goodyear: Investing in Kansas Plant Link...

Goodyears is planning to invest $125 million over five years to modernize production of truck and OTR tires at its plant in Topeka.

Goodyear: Demonstration Truck Tire with 63% Sustainable Material Content Link...

During IAA Transportation, Goodyear presented an innovative demonstration truck tire made with 63% sustainable-material content, demonstrating the company’s focus on selecting more sustainable materials for its products. The 63% sustainable-material demonstration truck tire includes 15 featured ingredients across 20 tire components, including those described below. This demonstration tire is labelled “A” in fuel efficiency meaning it can offer the same fuel saving as the most efficient Goodyear truck tires currently offered.

- Carbon black is included in tires for compound reinforcement and to help increase their tread life and has traditionally been made by burning various types of petroleum or coal tar-based products. This demonstration tire features four different carbon blacks that are produced from plant-based oil, end-of-life tire pyrolysis oil, carbon dioxide capture and conversion and a low-carbon methane pyrolysis process.

- Some of the petroleum-based oils in this demonstration tire were replaced by the use of rapeseed oil. Rapeseed oil is a bio-based resource that helps keep a tire's rubber compound pliable in changing temperatures. The use of bio-based rapeseed oil is in line with the company's goal of fully replacing petroleum-derived oils in its products by 2040.

- Silica is an ingredient often used in tires to help improve grip and reduce fuel consumption. This demonstration tire contains a unique variety of silica produced from rice husk ash, a byproduct of rice processing that is often discarded and put into landfills. A high-quality silica has been produced from this waste ash.

- Polyester is recycled from plastic bottles and other plastic waste by reverting the polyester into its base chemicals and reforming them into technical grade polyester feasible for tire cords, which enables better retreadability.

May (2022)

Goodyear: First Goodyear Truck Tires using Soybean Oil Compound Link...

Goodyear is replacing a portion of the petroleum-based materials used in production of some of its most popular Metro Miler city transit tires with a bio-based soybean oil compound. This is part of Goodyear's initiative to fully replace petroleum-derived oils by 2040. 11 liquid ounces of free-flowing petroleum oil is being replaced per tire.

March (2022)

Goodyear: Planning to Modernise French, Amiens Plant Link...

Goodyear has announced plans to modernize its tire manufacturing plant in Amiens over the next five years. The proposed project will strengthen the competitiveness of the plant through a high degree of digitalization, automation and equipment upgrades for more sustainable and innovative production of premium, large-rim-diameter consumer tires, including those for electric and hybrid vehicles.

January (2022)

Goodyear: Develops Tire with 70% Sustainable Materials Content Link...

Goodyear has announced the release of a demonstration tire with 70% sustainable-material content, including industry-leading innovations. The 70% sustainable-material tire includes 13 featured ingredients across nine different tire components and includes the following: - Carbon Blacks: from three different processes using methane, carbon dioxide and plant-based oil feedstocks.

- Soybean Oil: reduces reliance on petroleum-based products.

- Rice Husk Silica: produced from waste ash left after rice processing.

- Polyester: recycled from plastic bottles and other waste and coverted into tire cords.

July (2021)

Goodyear: Airless Tire for City Autonomous Vehicle Transportation Link...

Goodyear has developed an airless tire and wheel assembly to support autonomous vehicle transportation in a city setting for in-field use with the Jacksonville Transportation Authority (JTA). For the past three years, Goodyear and Local Motors have tested an Olli shuttle supported by the airless tire assembly at Goodyear testing facilities and other locations reaching several performance targets with respect to load, speed and durability. Goodyear and Local Motors will gather experiential data from the JTA, looking for viewpoints on ride comfort, noise and other variables.

June (2021)

Goodyear: Tire Intelligence Technology 'Goodyear SightLine' for Cargo Van Fleets Link...

Goodyear have announced the first tire intelligence solution for cargo van fleets, Goodyear SightLine. This will help enable seamless, safe and reliable mobility for all vehicles starting with cargo vans serving the field service, construction and last-mile delivery industries. Initially available in North America and Europe, Goodyear SightLine uses sensors with cloud-based algorithms to communicate with fleet operators in real-time. Goodyear’s proprietary predictive maintenance technologies can help to address many challenges facing drivers and fleet managers today, including predicting breakdowns, minimizing downtime and monitoring tire pressure and wear for enhanced safety and more cost-efficient mobility.

Goodyear: Completes Acquisition of Cooper Link...

Goodyear has completed its acquisition of Cooper Tire & Rubber Company. Goodyear plans to integrate the companies complementary business models in order to benefit its shareholders, customers, consumers and employees

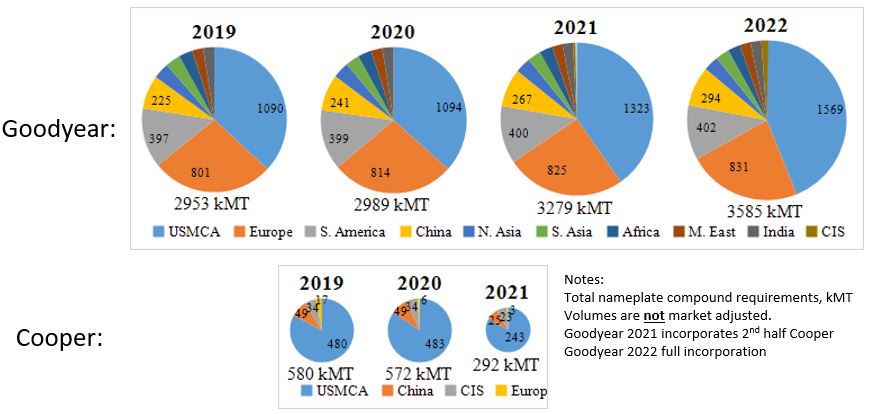

RCCL Industry Analysis:

Analysis Snippet: Goodyear Acquisition of Cooper

Goodyear and Cooper are actively adjusting production capacities and product mix. These factors are incorporated into the total nameplate compound capacity requirements (shown below) for the two companies just before the acquisition and for Goodyear post acquisition. Market adjusted capacities, splits by product type and other detailed analysis by region, manufacturer and year are available by request.  Contact Us For Further Information » Contact Us For Further Information »

March (2021)

Goodyear: Implementing Sustainable Procurement of Soybeans Link...

Goodyear have announced a new sustainable soybean oil procurement policy reflecting its commitment to responsible sourcing of materials and in support of its long term (2040) goal of full petroleum oil replacement in its products.

February (2021)

Goodyear: To Acquire Cooper Tire & Rubber Company Link...

Goodyear Tire & Rubber Company has entered into a definitive transaction agreement to acquire Cooper Tire & Rubber Company. The transaction is subject to the satisfaction of customary closing conditions, including receipt of required regulatory approvals and the approval of Cooper shareholders. The transaction is expected to close in the second half of 2021.

November (2020)

Goodyear: Collaboration wit TuSimple for Autonomous Vehicle Freight Operations Link...

Goodyear has announced a strategic relationship with TuSimple, a global autonomous trucking technology company, to provide tires and tire management solutions to TuSimple's Autonomous Freight Network (AFN). Goodyear will provide products and repair services for enhanced safety operation of autonomous trucks. The companies will also conduct wear studies for increased understanding, the data collected will provide insights into the differences between autonomous and human drivers with respect to tire wear.

April (2020)

Goodyear: Closing Gadsden, Alabama Plant Link...

Goodyear have reached a tentative bargaining agreement, subsequently approving a plan to close its Gadsden, Alabama plant. This is part of Goodyear's strategy to strengthen the competitiveness of its manufacturing footprint by curtailing production of tires for declining, less profitable segments of the tire market. The tentative bargaining agreement remains subject to approval by the membership of the local union.

March (2020)

Goodyear: reCharge Concept Tire Link...

Goodyear has uveiled its latest concept tire - the Goodyear reCharge.

The Goodyear reCharge is a revolutionary self-regenerating concept tire that can adapt and change to meet individual mobility needs. The reCharge concept includes a number of innovative features that are built around three pillars: - Personlised

- A reloadable and biodegradable tread compound that can be recharged with individual capsules, radically simplifying the process of replacing your tires.

- Sustainable

- The compound would be made from a biological material reinforced with fibres inspired by one of the toughest natural materials in the world - spider silk.

- Low-Maintenance

- A robust low-maintenance construction that would eliminate the need for pressure maintenance or downtime related to punctures.

February (2020)

Goodyear: First to Achieve OE Tire with 3PMSF and A Rated Rolling Resistance Link...

Goodyear has become the first company to produce an OE all-season tire with the 3PMSF (verified winter performance) which is also rated A (most efficient) for rolling resistance. The product represents close collaboration between functions and teams at Goodyear's Luxembourg and German developmen facilites and leverages the most recent tread pattern developments as well as new rubber compounding.

January (2020)

Goodyear: Advancing Future Mobility with Goodyear Ventures Fund Link...

Goodyear has announced a new venture capital fund, Goodyear Ventures, with $100 million targeted for new investments in future mobility solutions over the next 10 years. Goodyear Ventures will continue and expand Goodyear’s growing relationships in new mobility, with a focus on partnering and investing in startups with a shared vision of sustainable, safe and new mobility experiences that make life’s connections easier every day. Goodyear Ventures will focus on eight themes: - Electric and autonomous technologies

- Connected mobility solutions

- Next-generation public mobility

- Next-generation aviation mobility

- Future transportation infrastructure

- Future maintenance and operations

- Emerging technologies

- New tire materials

September (2019)

Goodyear: Planning to Replace Petroleum-Derived Process Oils with Soybean Oil by 2040 Link...

According to Goodyear's 2018 CSR the company is planning to replace petroleum-derived processing oils with soybean oil in its tires by 2040. The short term goal is to increase its soybean oil consumption by 25% by 2020.

Goodyear currently produces three tire lines using soybean oil: Assurance WeatherReady, Eagle Exhilarate and Eagle Enforcer All-Weather.

August (2019)

Goodyear: Planning Restructuring in USA Link...

Goodyear revealed that it is planning to restructure its US operations in order to improve competitiveness. The plan being studied aims to reduce low-value, high cost capacity in the US. The plans are of similar scale and benefit to those being undertaken by Goodyear in Germany. These plans were highlighted in the recent Q2 financial analysis call.

April (2019)

Goodyear: Expanding OTR Production at Colmar-Berg Plant, Luxembourg Link...

Goodyear have annouced plants to invest $36 million to increase OTR tire production at its Luxembourg, Colmar-Berg plant.

March (2019)

Goodyear: Modernisation Plans for Hanua and Fulda Plants in Germany Link...

Goodyear has approved plans to modernise its tire plants in Hanau and Fulda, Germany. The capacity for larger diameter tires will be increased over the next 2 to 3 years. The plan is subject to consultation with the relevant employee representative bodies with a potential to eliminate around 1000 jobs at the two facilities.

February (2019)

Goodyear: Planning Layoffs at Gadsden, Alabama Plant Link...

Goodyear is planning to reduce tire production at the Gadsden, Alabama plant in Q2 with an associated reduction in the work force.

December (2018)

Goodyear: Expanding Slovenian Tire Plant Link...

Goodyear is planning to expand capacity at its Kranj plant in Slovenia by adding capabilities for larger diameter tires. The expansion will expand capacity by 1.8 million tires pa and will be complete by 2022.

Goodyear: Ceasing Production at Venezuelan Factory Link...

Goodyear is to cease production at its Venezuelan factory due to economic conditions. Severance payments reportedly include provision for giving each employee 10 tires due to their high value in a country with severely limited resources.

September (2017)

Goodyear: New Luxembourg Plant for Small Batch High Value Tires Link...

Goodyear announced plans at the facilities groundbreaking event to create a new facility in Luxembourg for small batch production of high value tires using Goodyear's innovative Mercury production process. The Mercury process features highly automated interconnected workstations using additive manufacturing technologies to efficiently product premium tires in small batches.

November (2016)

Goodyear: Expands Pulandian, China Factory Link...

PULANDIAN, China, November 2, 2016 -- The Goodyear Tire & Rubber Company today announced it has broken ground on a $485 million expansion of its state-of-the-art tire factory in Pulandian, Dalian, China. When completed in 2020, the expansion will increase the plant’s capacity by about 5 million tires a year, enabling Goodyear to meet the strong and growing market demand for premium, large-rim-diameter consumer tires in China and the Asia Pacific region. By 2020, Goodyear expects tires with rim diameters of 17 inches or greater to account for nearly 60 percent of its replacement tire sales volume in China.

October (2016)

Goodyear: Planning to close Philippsburg Plant, Germany Link...

Goodyear is planning to close its Philippsburg plant in Germany by end of 2017. This is part of Goodyear's focus to concentrate on premium, larger diameter tires.

RCCL Industry Analysis:

Analysis Snippet: Goodyear Philippsburg Estimated impact is the loss (or shift) of approximately 40 kMT of rubber compound affecting about 9 kMT of carbon black and 5 kMT of precipitated silica. Note: In order to put these changes into context, it is necessary to understand the regional and global product shifts. Goodyear have implemented a number of product mix changes as well as capacity increases in other locations. The full effects of this and other industry changes are automatically incorporated into RCCL rubber chemical reports. Further detailed analysis for can be made by arrangement.

Goodyear: Planning to Close Pant in Philippsburg, Germany Link...

October 24 the company announced its intention to close its Philippsburg, Germany tire manufacturing facility and realign its European capacity to increase production of high-value-added tires.

September (2016)

Goodyear: Considering Investment in Topeka Link...

Goodyear is considereing making investments in its Topeka truck and earthmover factory.

Goodyear: Goodyear Outlines Growth Plan Link...

Goodyear is budgeting nearly $800 million through 2019 to boost production capacity for HVA tires (nominally those with 17" diameter or greater). The plan includes 125 MM$ for 2 MM units at Lawton and Fayetteville for OE products. 210 MM$ by 2019 for 3MM additional units in China, 115 MM$ for 1MM additional uints at Aurangabad, 290 MM$ by 2019 for 6MM additional units in Mexico, 20 MM$ for 1 MM units at Uitenhage, South Africa.

August (2016)

Goodyear: Planning New Raidal Aircraft Plant in Thailand Link...

Bangkok – Goodyear Thailand is planning tobuild a new radial aircraft tire plant at its Pathum Thani manufacturing site. First of 3 phases will be compete by 2018.

July (2016)

Goodyear: Expanding PC Tire Capacity in China Link...

Goodyear is increasing PC capacity by 3 million units at its Dailan plant.

October (2015)

Goodyear: Officially Dissolved Sumitomo Global Alliance Link...

Goodyear and Sumitomo have officially dissolved their global business alliance.

June (2015)

Goodyear: Reach Agreement with Sumitomo Rubber Industries to Dissolve Global Alliance Link...

AKRON, Ohio, June 4, 2015 – The Goodyear Tire & Rubber Company announced today that it has reached agreement with Sumitomo Rubber Industries, Ltd. (SRI) to dissolve the global alliance between the two companies.

Goodyear and SRI formed the global alliance in 1999. It primarily consists of four joint venture operating companies, one each in North America and Europe, and two in Japan.

Goodyear: Rationalisation Plant in Europe Link...

Plans to close the Wolverhampton UK mixing and retreading facility and to consolidate production in Europe with relocation of PC tire production from Wittlich to other plants.

May (2015)

Goodyear: Introduces Tires Containing Next Generation Silica Link...

AKRON, Ohio, May 5, 2015 – The Goodyear Tire & Rubber Company has begun using a next-generation silica to increase the fuel-efficiency of its tires. This new silica will be first used in the Goodyear EfficientGrip SUV tire, which is being launched this month in Latin American markets. Tires containing the silica also will be introduced in other regions within the next year.

For more than a decade, Goodyear researchers worked with PPG Industries to examine the effects of chemically treated silica on tire performance. The goal was to further improve rolling resistance without have a detrimental effect on traction in wet conditions. In Goodyear’s new EffcientGrip SUV tire, this next generation silica was used in a new tread compound and a new tread pattern to provide both improved rolling resistance and improved wet traction.

April (2015)

Goodyear: To Build Tire Factory in San Luis Potosi, Mexico Link...

MEXICO CITY, April 24, 2015 – The Goodyear Tire & Rubber Company today announced it will build a new tire factory in San Luis Potosi, Mexico to serve its customers in the Americas. Goodyear Chairman and Chief Executive Officer Richard J. Kramer made the announcement here today at a ceremony with Mexican President Enrique Peña Nieto.

The new factory, combined with investments in its existing U.S. and Canadian factories, will enable Goodyear to meet the strong and growing market demand for high-value-added (HVA) consumer tires in North America and Latin America. Industry demand for HVA tires in these regions is expected to increase by 10 million tires per year from 2014-19.

March (2015)

Goodyear: Establishes Tire Development Center in China Link...

PULANDIAN, China – March 26, 2015 – The Goodyear Tire & Rubber Company announced today that it has established its first development center in China.

Located at the company’s state-of-the-art tire manufacturing facility here, the new center expands Goodyear’s capabilities in the Asia Pacific region and will enable it to increase the speed and efficiency of high-value-added tire development, especially for China-based automakers.

Goodyear: Initiating third phase of Dalian plant expansion Link...

Increasing capacity by just over 2 million PC tirers including run flats, final capacity will be installed by 2017.

September (2014)

Goodyear: Converts Waste from Rice Harvest to Fuel-Efficient Tire Treads Link...

AKRON, Ohio, September 22, 2014 – Rice husk waste once headed for landfills is now helping The Goodyear Tire & Rubber Company produce fuel-efficient tires. Goodyear today announced it will utilize ash left over from the burning of rice husks to produce electricity as an environmentally friendly source of silica for use in its tires.

May (2014)

Goodyear: Announces Plan to Build New Consumer Tire Plant in the Americas Link...

AKRON, Ohio, May 29, 2014 – The Goodyear Tire & Rubber Company today announced an update to its 2014-2016 capital allocation plan focused on increasing shareholder returns and capturing high-return growth opportunities in North America and Latin America. Goodyear plans to invest approximately $500 million to build the new plant, which will be its most technologically advanced and have an initial capacity of about six million tires per year. Capacity can be increased as demand increases. Site selection is underway to identify the best location for the plant to support North America and Latin America customers. Tire production is expected to begin in the first half of 2017.

January (2011)

Goodyear: Business Strategy Link...

Goodyear are focusing on plant upgrades to higher value products - capital plans have been outlined for Chile, Brazil and Germany.

Titan International Inc: Finalises Acquisition of Goodyear Sao Paulo Farm Tire Business Link...

The transaction included Sao Paulo's manufacturing plant, property, equipment and licensing agreement similar to the North American Goodyear farm asset purchase in 2005.

|